Precision redefined

A cutting edge nuclear industry research customer needed a high vacuum radiation resistant LSOH multicore cable that would also meet the CPR rating Cca

The Problem

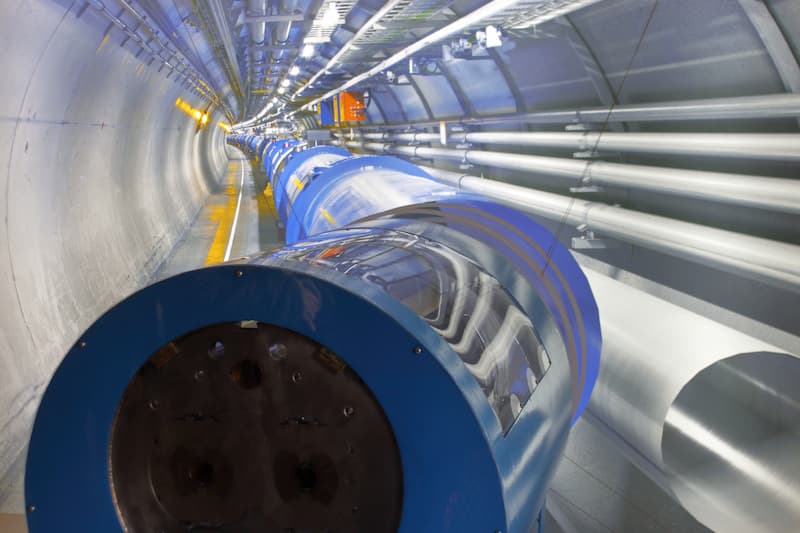

This bespoke multicore cable was required for a project upgrade of the CMS detector which is part of the large hadron collider at CERN.

The detector area has ionizing radiation levels in excess of 100 MRADS. Initial requirement was for a low voltage 7 core cable. Another strict requirement was for compact design due to space constraint.

The Solution

Heatsense created a 7 core design that fulfilled all customer’s requirements, accordingly a further enquiry was requested for a more complex high voltage multicore cable.

Heatsense offered a solution that met and exceeded both requirements. Customer satisfied and both cables were ordered.