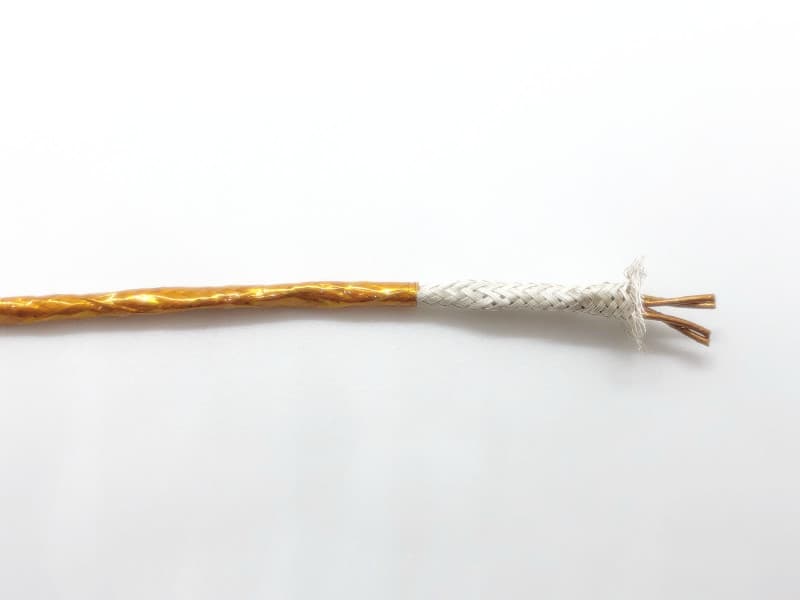

Heatsense’s range of radiation resistant cable and wires are designed to operate in areas where safety is critical and radiation tolerance is required.

Radiation-resistant cables are specifically designed to function reliably in environments with high levels of ionizing radiation, such as nuclear power plants, particle accelerators and medical equipment. These cables are engineered to withstand prolonged exposure to radiation without degradation in performance.

Common applications include, aerospace, space, nuclear, military and defence systems, medical imaging equipment and R&D facilities.

Click on the datasheet links below to see our full product range or get in touch about a specific requirement you have.

What materials are used to provide radiation resistance?

Due to its excellent radiation resistance, Polyimide is frequently used in high radiation environments where a thin, flexible insulating material is required. In outer space, Polyimide is used both alone and in combination with other materials where radiation resistance and minimum weight is necessary. Polyimide is also used in nuclear reactors and linear accelerators.

Other insulations include ETFE and PEEK.

Cable types available with radiation protection

Single wires can be used to create multi-conductor constructions and thermocouple types.

Can't find what you need?

Radiation Resistant Cable Downloads

You may also be interested in

Heat Resistant Cables

Aerospace Cables

Radiation Resistant

Oil & Gas Cables

General Industry Cables