At Heatsense Cables, we design and manufacture radiation resistant cables and wires engineered to perform in the harshest nuclear, aerospace, medical, and research environments.

From nuclear submarines to satellites and fusion reactors, our cables are built to maintain electrical and mechanical integrity under exposure to gamma rays, neutron flux, high-energy particles, extreme heat, vacuum, and corrosive atmospheres.

Standard polymer-insulated cables such as PVC or polyethylene degrade rapidly when exposed to ionising radiation. That’s why Heatsense develops bespoke cable solutions that combine advanced materials science, rigorous testing, and decades of engineering expertise.

Click on the datasheet links below to see our full product range or get in touch about a specific requirement you have.

Types of Radiation Resistant Cables

Mineral-Insulated (MI) Cables

- Construction: Stainless steel, Inconel, or copper sheath; compacted magnesium oxide or alumina insulation.

- Radiation Tolerance: Beyond 10⁹ Gy with zero degradation.

- Applications: Nuclear reactor in-core detectors, spacecraft thermocouples, aerospace turbines.

- Advantages: Non-flammable, stable above 1000 °C, unmatched reliability.

- Limitations: Rigid, higher cost, requires skilled installation.

Polyimide and Composite Insulations

- Construction: Tape-wrapped polyimide (e.g. Kapton®) with fluoropolymer or glass reinforcement.

- Radiation Tolerance: Up to 10⁷ Gy, with excellent dielectric stability.

- Applications: Satellites, fusion reactors (ITER), high-energy physics labs.

- Advantages: High temperature rating, lightweight, vacuum compatible.

- Limitations: Can crack under mechanical stress, hydrolytic weakness in humidity.

Fluoropolymer-Insulated Cables

- Materials: PTFE, FEP, PFA, ETFE, and crosslinked blends.

- Radiation Tolerance: 10⁵–10⁶ Gy, with enhanced performance through crosslinking.

- Applications: Aerospace harnesses, control room cabling in nuclear plants, medical accelerators.

- Advantages: High flexibility, strong chemical resistance, excellent dielectric properties.

- Limitations: Embrittlement under neutron radiation, performance drops over time.

Crosslinked Polyolefins & Elastomers

- Materials: XLPE, EPR, silicone rubber blends with stabilisers.

- Radiation Tolerance: 10⁴–10⁵ Gy, with good flexibility and resilience.

- Applications: Nuclear power plant distribution cables, submarines, cost-sensitive defence projects.

- Advantages: Balance of electrical and mechanical properties.

- Limitations: Radiation-induced oxidation over time reduces elongation.

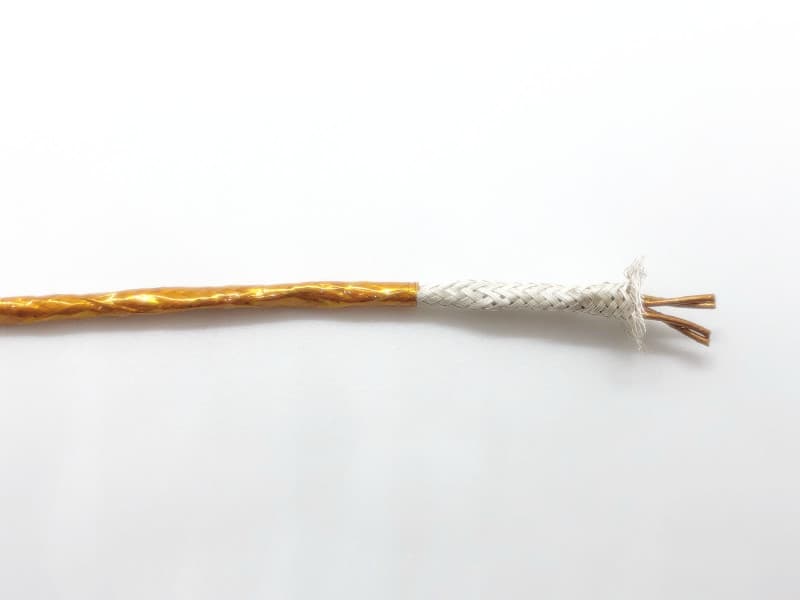

Ceramic-Insulated & Hybrid Designs

- Construction: Glass-braided, mica tape, or ceramic fibre insulation, often combined with metal jackets.

- Radiation Tolerance: 10⁸ Gy+ (fully inorganic designs).

- Applications: Safety-critical nuclear shutdown systems, fire- and radiation-survivable defence cables.

- Advantages: Outstanding combined resistance to fire, radiation, and chemicals.

- Limitations: Brittle, more complex installation.

Can't find what you need?

Radiation Resistant Cable Downloads

Applications of Radiation-Resistant Cables

Heatsense cables are already deployed across multiple critical industries:

- Nuclear: Reactor control, in-core sensors, radiation-hardened instrumentation.

- Aerospace & Space: Satellites, space probes, engine harnesses for extreme vibration/heat + radiation.

- Defence: Submarine cabling and high-security communication systems.

- Medical: Radiotherapy and imaging equipment requiring radiation-hardened wiring.

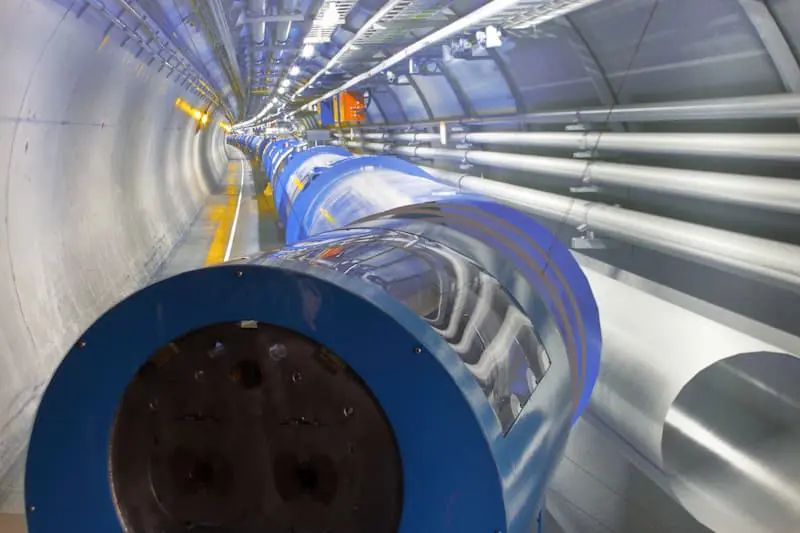

- Research: Particle physics laboratories (CERN, Fermilab), ITER fusion reactors.

Why Radiation Resistance Matters

Radiation fields degrade organic polymers and metals through ionisation, scission and cross-linking mechanisms. This leads to embrittlement, insulation breakdown, and loss of dielectric strength. Depending on the application, cables may need to withstand cumulative doses ranging from 10⁴ to more than 10⁹ Gy, while also tolerating high temperatures and chemical attack.

Our cables are designed to meet or exceed the strict standards of:

- Nuclear industry: IEC 60544, IEEE 383, RCC-E

- Aerospace and space: NASA/ESA, ESCC specifications

- Medical & research: Particle accelerators, radiotherapy facilities, CERN, ITER

Innovation and Future Development

At Heatsense, we continually push the boundaries of materials science and cable design. Current research includes:

- Nanofiller-enhanced polymers to reduce radiation-induced chain scission.

- Radiation-hardened composites combining inorganic/organic insulation.

- Flexible ceramic yarn braids for cables that survive fire + radiation in defence and nuclear safety systems.

By working closely with customers, we create bespoke cable solutions that meet specific environmental challenges and strict tolerance requirements.

Performance Considerations

Radiation resistance is not a single property but a combination of:

- Total Integrated Dose tolerance.

- Synergistic effects of temperature, vacuum and mechanical stress.

- Dose-rate effects, where rapid exposure can induce different failure modes compared to long-term low-dose accumulation.

- Neutron vs. gamma resistance, since neutron displacement damage primarily affects metals and ceramics, while gamma degradation is dominant in polymers.

Applications and Industry Standards

-

Nuclear Industry: IEC 60544, IEEE 383, RCC-E standards for safety-class cables.

-

Aerospace/Space: NASA/ESA specifications, ESCC standards for fluoropolymer/polyimide harnesses.

-

Medical and Industrial Accelerators: Customized fluoropolymer/polyimide blends for high-dose x-ray and proton beamlines.

-

Research Facilities: CERN, Fermilab and ITER employ hybrid designs combining mineral-insulated sensors with polyimide or fluoropolymer signal cables.

Future Research

- Nanofiller-enhanced polymers: Incorporating silica, alumina, or graphene to reduce chain scission under irradiation.

- Radiation-hardened composites: Hybrid layering of inorganic/organic insulation.

- Advanced ceramics: Flexible ceramic yarn braids for next-generation fire and radiation-survivable cables.

- Qualification testing: Improved accelerated radiation testing protocols to predict lifetime performance under complex multi-stress environments.

Our View of the Future

Radiation-resistant cables represent a multidisciplinary field spanning metallurgy, polymer science, nuclear engineering and aerospace technology. The choice of cable type is application-specific: mineral-insulated and ceramic-based designs dominate in extreme nuclear or space environments, while fluoropolymers and polyimides provide balance for aerospace and accelerator uses.

With emerging challenges in fusion energy, deep space missions and next-generation reactors, innovation in materials and qualification testing will remain essential.

You may also be interested in

Heat Resistant Cables

Aerospace Cables

Radiation Resistant

Oil & Gas Cables

General Industry Cables